1. The shell is made of high-strength ductile iron and high-strength alloy steel, with high overall structural strength.

2. The reducer adopts a planetary structure design, with a compact structure and smooth operation.

3. The transmission gears all adopt hard tooth surface grinding technology, which has high efficiency, low noise, and long service life.

4. The output shaft is subjected to overall quenching treatment to prevent shaft breakage.

5. All seals are made of Taiwanese brands.

6. High quality (Mobil, Uni President) lubricants.

7. Using global top brand bearings to ensure smooth transmission and low noise.

8. This series of reducers can be equipped with torque motors and variable frequency motors.

|

Product model

|

Transmission ratio (i) |

Output torque (N.m) |

Output gear Normal modulus |

Output gear Number of teeth |

Output gear Displacement coefficient |

Weight (kg) |

Motor power (kw) |

Recommended tower crane (t.m) |

|

| LNTH13-195 | 195 | 13000 | 10 | 16 | 0.5 | 150 | 9 | 160-250 | |

| LNTH13-195B | 195 | 10000 | 12 | 17 | 0.55 | 150 | 3 | 50-125 | |

| LNTH13-195C | 195 | 10000 | 12 | 14 | 0.5 | 150 | 4 | 50-125 | |

| LNTH13-195D | 195 | 10000 | 12 | 16 | 0.5 | 150 | 4 | 50-125 | |

.jpg)

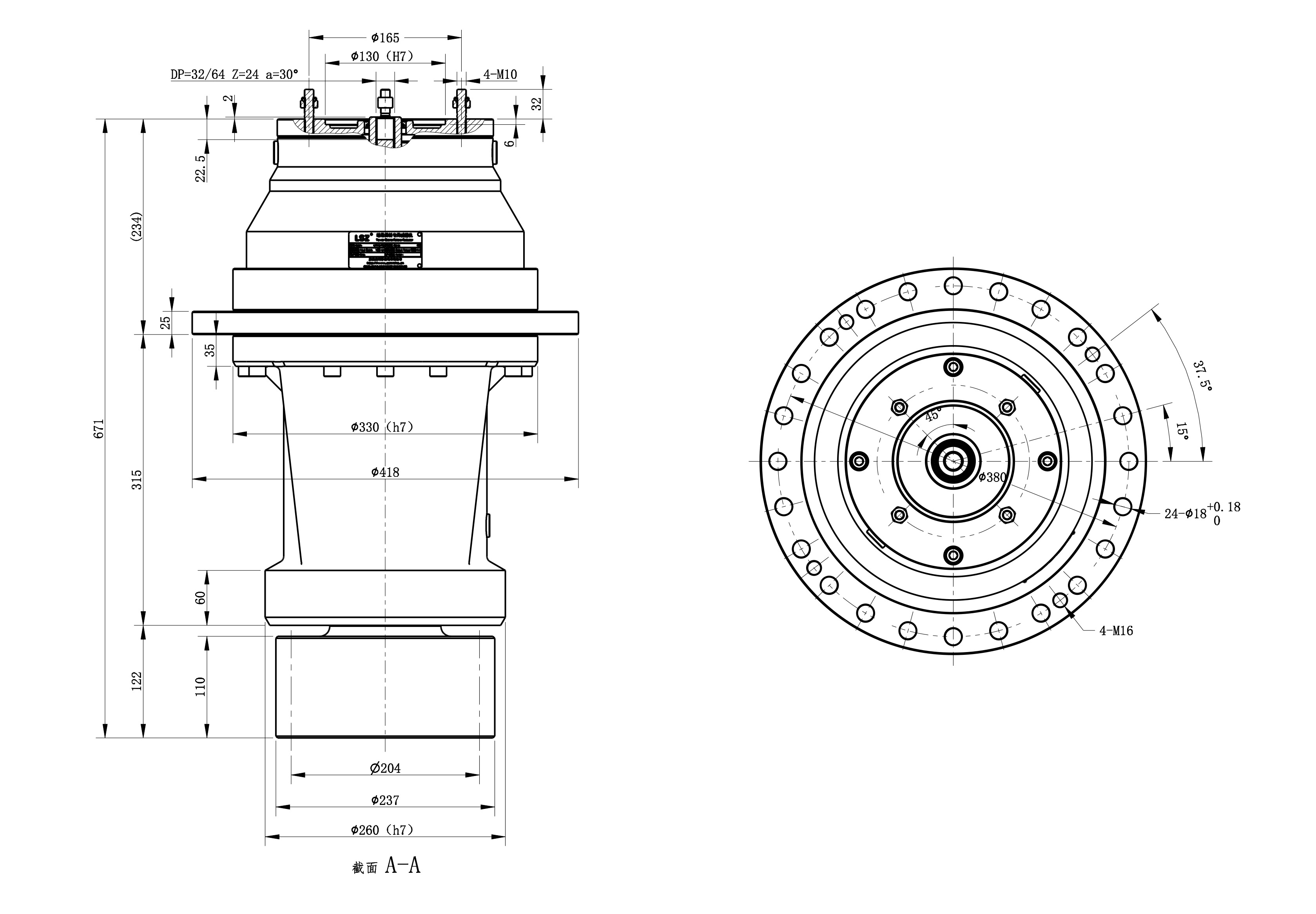

Product model:LNTH13-195

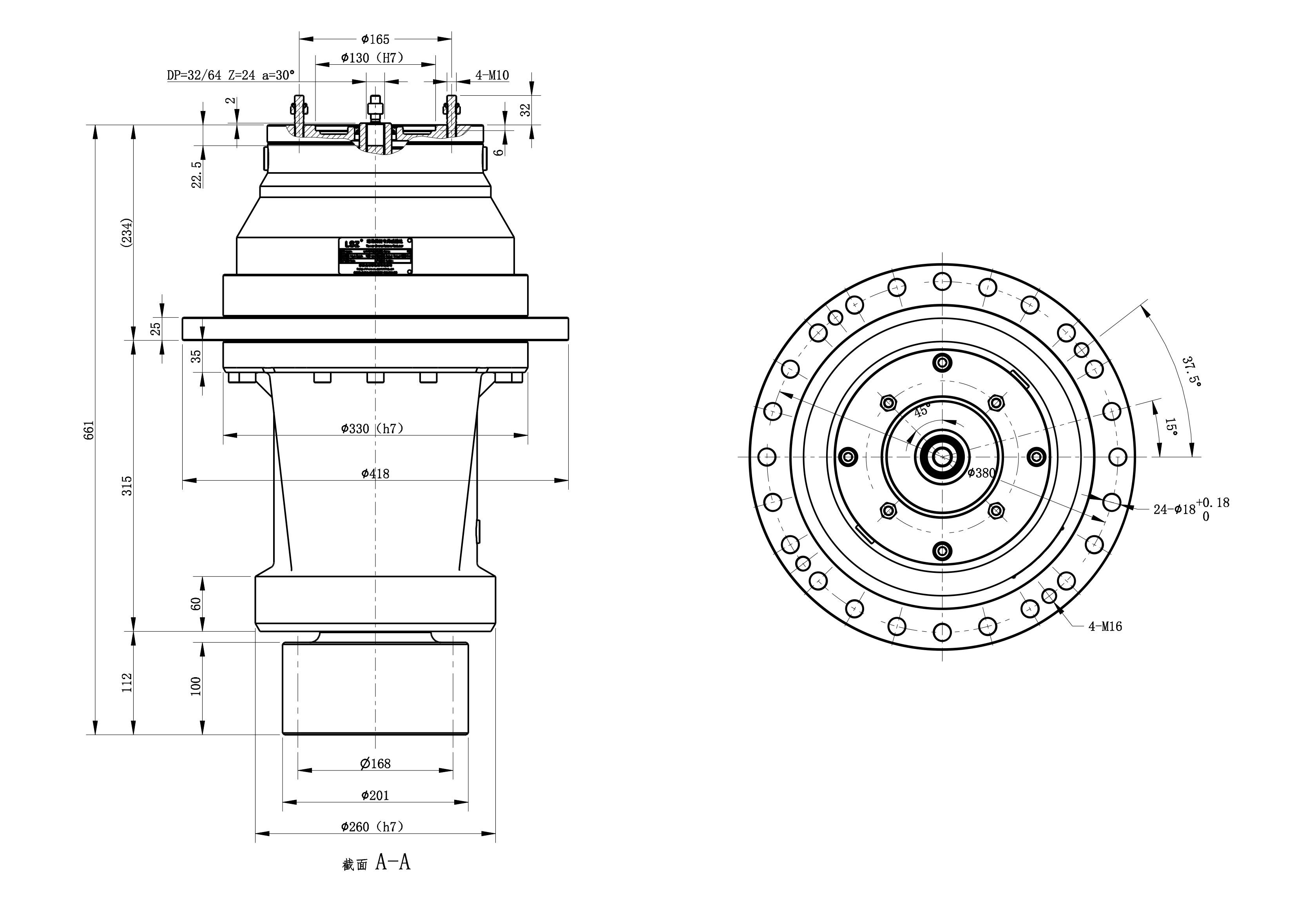

Product model:LNTH13-195B

Product model:LNTH13-195C

.jpg)

Product model:LNTH13-195D

中文

中文